Carving Rings

This post is dedicated to the memory of Julian Guy Tulloch, who died peacefully on the 12th December 2010, aged 78.

Julian first introduced me to carving.

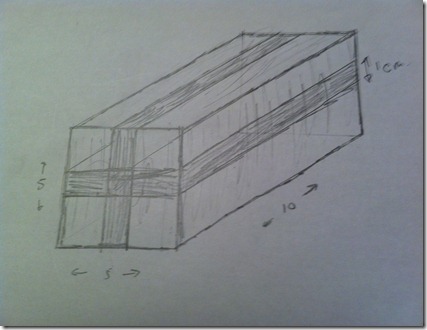

We start with a small block of wood, 5cm by 5cm by 10cm. The exact dimensions are not too important, you just want a block of wood that is rectangular in nature with a square end:

I’m using Tilia or Basswood which is good for carving – not too dense and very little grain. You can find this type of wood at craft shops, often described as ‘Carving Blocks’.

Extruded Cross

The first step is to mark out an extruded cross using a pencil:

I made the cross 1cm wide. The cross is drawn on the two square ends of the block of wood and joined up over the length of the block. Note, the extruded cross is the shaded area on the diagram.

Now, using a small Tenon Saw, you should remove the four corner pieces. These are the un-shaded areas in the diagram above. This should leave the extruded cross:

Notice that I don’t cut right up to the line. I leave a little margin for error when using the saw. To finish off the extruded cross, I use a carving/milling tip on my Dremel hand tool:

So far, so good. Now for a little vacuuming!

Overlapping Discs

Next we need to transform our extruded cross into two overlapping discs. The discs are inside the cross, you can see them on the diagram below:

Because my cross was 5cm across the face, the discs are 5cm in diameter:

The important bit is the overlap. One disc needs to overlap the other. There needs to be sufficient overlap to carve out the rings, one from each disc. I have decided to have each disc overlap half way through the other disc.

Again, I will use my Tenon Saw to cut away the excess wood. First step is to remove two end pieces – ‘A’ and ‘B’ on the diagram below:

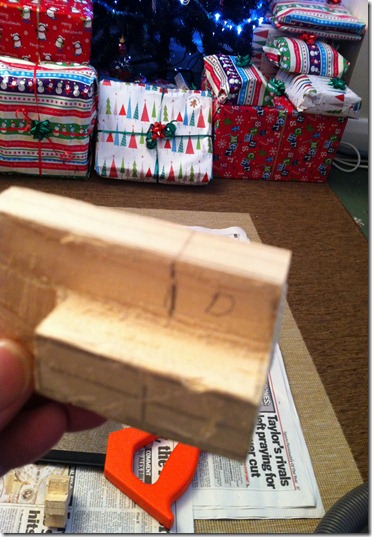

On the carving, the areas to remove are shown marked A and B:

After cutting away the wood with the saw we have the following:

Now we have to remove the rest of the excess wood. In the diagram below, this is marked ‘C’, ‘D’ and ‘E’:

‘C’ is a complete bit of the extruded cross and we remove this using the saw:

Can you see the two overlapping discs yet?

Ok, now remove the little pieces ‘D’ and ‘E’. This is the same as ‘A’ and ‘B’. Look, two overlapped blocks:

It is worth marking out the discs and removing the excess wood to reveal the discs. First, mark out the discs with a pencil. I’m draw these by hand:

Then remove the excess wood. I’ve used my Dremel for this but carving chisels or even sanding will work. And now we have two interlinked discs:

Again, let’s tidy up.

Finding the Rings

My discs are 1cm wide. Because of this, my rings are going to be roughly 1cm in diameter before any sanding.

At this point the rings are embedded in the edge of the discs. We need to define the rings by removing the centre of the discs. We are going to do this in two steps. The first step is to clear the majority of the centre of each disc. We will still be left with ring connected together. The second step is to finally free the rings.

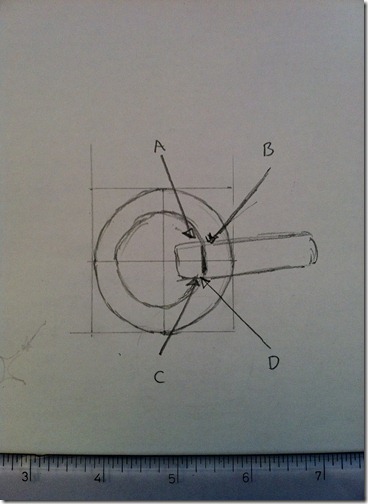

For each disc we want to remove the shaded area ‘A’ from as shown in the diagram below:

You must be very careful not to remove any of the ring or any of the second ring. The result should look like this:

OUCH!!! I cut my hand – be careful.

Ok, tricky bit coming up so time to tidy up and have a rest.

Tricky Bit – Free the Rings

This bit is a little tricky and can go badly wrong. If you remove too much wood, you may break the rings. The two rings are joined, but only by a small wall of wood. Take a close look at the rings and you can make this out.

The process for removing this wall and separating the rings is a little hard to describe but I will give it a go:

In the diagram above I’m looking down on one of the rings. There are four points on the top surface that need to be chiselled – ‘A’, ‘B’, ‘C’ and ‘D’ Similarly, from the bottom side of this ring, there are four more points – ‘E’, ‘F’, ‘G’ and ‘H’.

Notice that these 8 points are the 8 corners of a cube. Not a normal cube with straight sides, rather one with concave sides:

Try to see this in the rings before you start to carve. You want to chisel into these eight points as evenly as possible and when chiselling, you need to chisel diagonally towards the centre of the cube. Bit, by bit you have to remove the cube from the corners, outside to the centre. When the cube has been chiselled away, the rings will magically free:

Remember, don’t rush it and it should work.

Another tidy up.

Last step – Sanding and Varnish

To complete the rings, you need to sand away excess wood to reveal the rings. You can sand away until you are happy with the results. Again, be careful as you don’t want to spoil the rings at this stage. Once you have sanded to reveal the rings, you need to varnish the rings.

The trick with varnishing is to apply a coat, then sand away the coat. Then repeat. The more times you repeat this, the harder the finish.

Here are my rings, not yet varnished but fully revealed:

And after Varnishing

After more than 15 repeated varnish and sanding cycles, here is the finished article. Very hard finish with the wood grain showing through like Tiger Stone:

I’m very pleased with the results

Have fun and Happy New Year.

Wow, this is great! I really like what you've created. However not even a bit simple to me. :)

ReplyDeleteNigel, this is great. Sarah, Mum & I looked at it & are v impressed. What a lovely thing to have passed on. Well done you. Lovely rings. Our father would be proud.

ReplyDelete